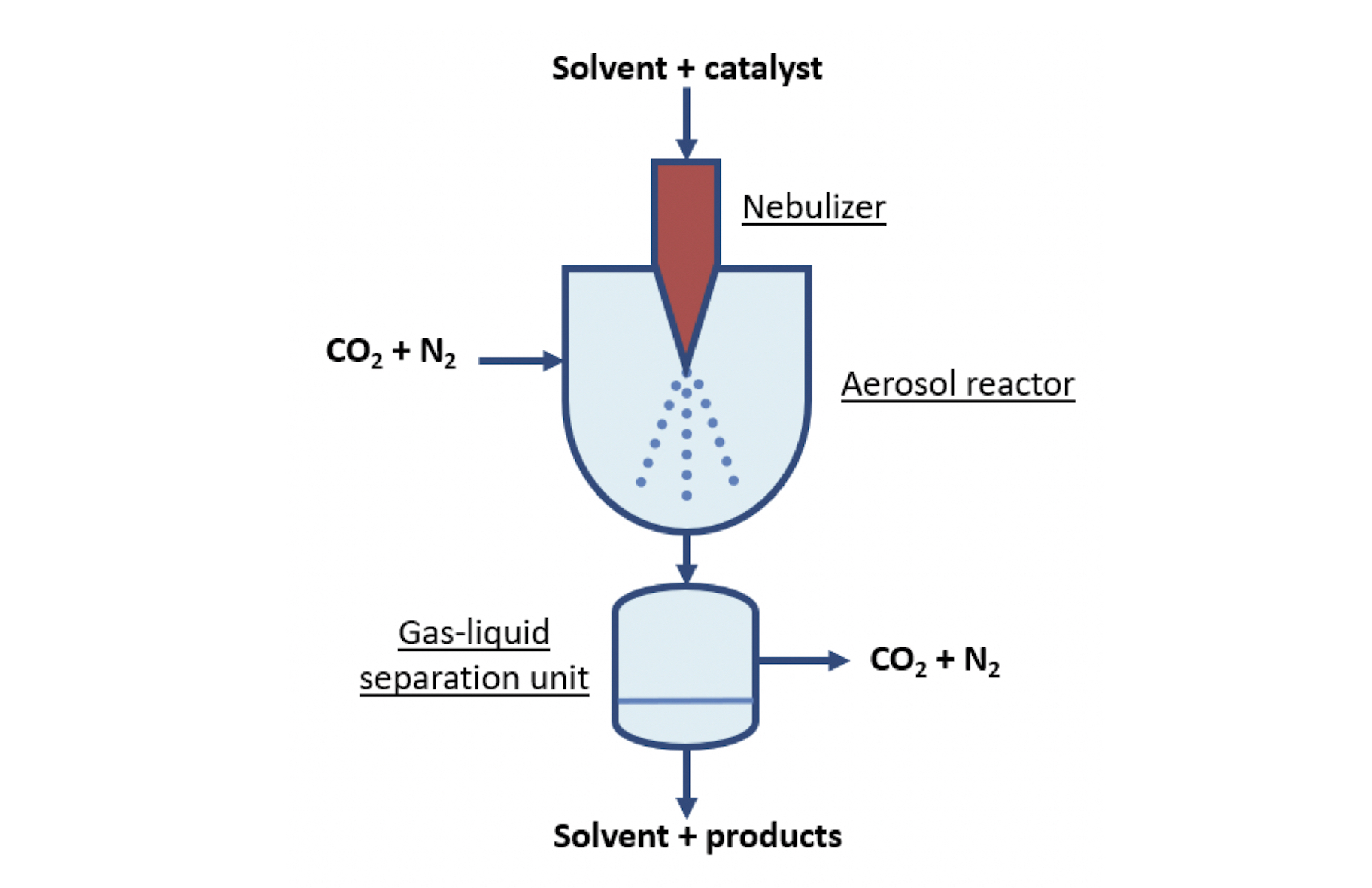

The use of microflow reactors enabled dramatic improvements in the apparent rates of photochemical reactions. However, scaling-up of micro photoreactors remains a challenge due to the difficulties of distributing light and flow to all units of microreactors. Aerosols alleviate the mass and photon transfer limitations forming an easily scalable micro-structured reactor. In this reactor concept, each droplet works as a microreactor. The Sauter mean diameters of the droplets at different pressures vary between 7 and 100 µm depending on nebulization technology and the solvent properties. The residence time ranges between 1 to 25 s. Aerosol reactor behaves like an ideal continuously stirred tank reactor.

A singlet oxygen mediated photosulfoxidation reaction has already been utilized as a model reaction to assess the reactor performance. The reaction rate was increased a hundred times compared to a literature study which was performed in vial with 1 mL working volume. The nature of aerosol light interaction enables better light distribution. It was shown with experimental data that the photon transfer limitations were overcome in the aerosol photoreactor. Mass transfer limitations were calculated by solving the convection-diffusion equation for a droplet. It was proven that the mass transfer limitations were overcome in an aerosol photoreactor for the first time. This work paves the way for efficient and scalable photoreactors for industrial use.